OIL TESTING

Transformer oil, a type of insulating and cooling oil used in transformers and other electrical equipment, needs to be tested periodically to ensure that it is still fit for purpose. This is because it tends to deteriorate over time. MPS conduct oil testing of transfomers as per the parameters mention in IS 1866.

Testing consists of measuring breakdown voltage and other physical and chemical properties of samples of the oil, either in a laboratory or using portable test equipment on site.

✔ Sampling & Collection of the sample.

✔ Oil test as per IS 1866 and fault diagnosis by DGA.

✔ Analysis of Furan.

✔ Maintaining data history of transformer.

OUR DIFFERENT TYPES OF LAB TESTING

COLOUR AND APPEARANCE

Color of oil in service indicates deterioration stage, Cloudiness indicates the presence of dissolved water & suspended particle of sediments indicates the products of oxidation.

The color of an insulating oil is determined in transmitted light and is expressed by a numerical value based on comparison with a series of color standards. It is not critical property but it may be useful for comparative evaluation.

Besides color the appearance of oil may show cloudiness or sediment, which may indicate the presence of free water, insoluble sludge, carbon particles, fibres , dust or other contaminants

DENSITY

In cold climates the density of oil may be important in determining its suitability for use. For example, ice crystals formed from separated water may float on oil high density and lead to flashover on subsequent melting. However density is not significant in comparing the quality of different oil samples.

Density may be useful for discriminating mineral insulating oil from the other fluid types.

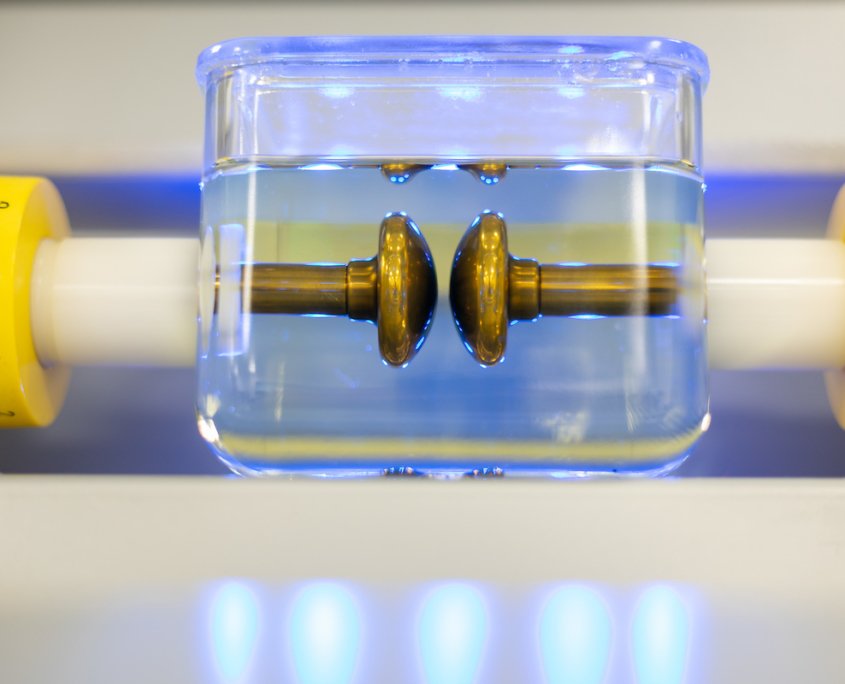

BREAK DOWN VOLTAGE

Indicates the presence of free water, dirt, conducting particles & moist cellulosic fibers.

Break down voltage is a measure of the ability of oil to withstand electric stress and has primary importance for the safe operation of electrical equipment .It is strongly dependent on the sampling temperature. Dry and clean oil exhibits an inherently high breakdown voltage. Free water and solid particles, the latter particularly in combination with high levels of dissolved water , tend to migrate to regions of high electric stress and reduce breakdown voltage dramatically.

The measurement of breakdown voltage, therefore serves primarily to indicate the presence of the contaminants such as water or particles. A low value of breakdown voltage can indicate that one or more of these are present. However a high breakdown voltage does not necessarily indicate the absence of all the contaminants.

NEUTRALIZATION VALUE

Indicates the acid content in the oil which increases corrosion of metal in the equipment & decreases Dielectric properties. The acidity (neutralization value) of oil is a measure of the acidic constituents or contaminants in the oil.

The acidity of a used oil is due to the formation of acidic oxidation products. Acids and the other oxidation products will in conjunction with water and solid contaminants, affect the dielectric and other properties of the oil acids have an impact on the degradation of cellulosic materials and may also be responsible for the corrosion of metal parts in a transformer.

The rate of increase of acidity of oil in service is a good indicator of the ageing rate. The acidity level is used as a general guide for the determination when the oil should be replaced or reclaimed.

WATER CONTENT

Indicates the total dissolved water in the oil which decreases the insulation value resistance of windings. Depending on the amount of water ,the temperature of the insulating system and the status of the oil , the water content of the insulating oils influences.

The breakdown voltage of the oil.

The solid insulation.

Ageing tendency of the liquid and solid insulation.

The water content in the liquid and the solid insulation thus has a significant impact on the actual operating conditions and the lifetime of the transformer. Hence this test undergoes to identify the amount of water content in the oil.

DIELECTRIC DISSIPATION FACTOR (DDF) AND RESISTIVITY

DDF indicates the presence of soluble varnish, polar contaminants & product of deterioration in the oil. Specific resistance indicates the absence of Conducting impurities & free-ion content in the oil which maintains a high insulation resistance of windings.

These parameters are very sensitive to the presence of soluble polar contaminants. Ageing products or colloids in the oil . Changes in the levels of the contaminants can be monitored by the measurement of these parameters even when contamination is so slight as to be near the limit of chemical detection.

Acceptable limits for these parameters depend largely upon the type of equipment. However, high values of DDF or low values of resistivity , may deleteriously affect the dielectric losses and/or the insulation of the electrical equipment.

INTERFACIAL TENSION

Indicates the presence of deterioration products of oil oxidation (Sludge) & excessive polar contaminants.

The interfacial tension between oil and water provides a means of detecting soluble polar contaminants and products of degradation. This characteristic changes fairly rapidly during the initial stages of ageing but levels off when deterioration is still moderate.

A rapid decrease of IFT may also be an indication of compatibility problems between the oil and some transformer materials (varnishes, gaskets) or of an accidental contamination when filling with oil.

With overloaded transformers, the deterioration of materials is rapid and IFT is a tool for the detection of deterioration.

FLASH POINT

Indicates the presence of lower hydrocarbon (i.e Highly Volatile & Flammable materials) in oil.

Breakdown of the oil caused by electrical discharges or prolonged exposure to very high temperatures may produce sufficient quantities of low molecular weight hydrocarbons to cause a lowering of the flash point of the oil.

A low flash point is an indication of the presence of volatile combustible products in the oil. This may result from contamination by a solvent but, in some cases, the cause has been observed to be extensive sparking discharges.

SEDIMENT AND SLUDGE

Indicates the deposition of sticky sludge & fibrous particle contamination which enhances the restriction in hit transfer & decreases insulation resistance of windings. The test distinguishes between sediment and sludge. Sediment is insoluble material present in the oil. The presence of sediment and/or sludge may change the electrical properties of the oil, and in addition, deposits may hinder heat-exchange ,thus encouraging thermal degradation of the insulating materials.

DISSOLVED GAS ANALYSIS

Hydrogen, Carbon Monoxide & Dioxide, Hydrocarbons and total Combustible Gas Contents Monitors the internal condition of the transformer. Also reveals the presence of incipient fault in the transformer & also gives a fair indication of the severity of the such fault.

Due to normal aging or internal faults different types of gases are generated which subsequently dissolve in oil. Hence dissolved gas analysis of the transformer oil gives indication of the nature of fault inside the transformer.

A sudden increase in key gases and the rate of gas production is more Important in evaluating a transformer than the accumulated amount of gas The advantages of dissolved gas analysis are as follow.

Advance warning of developing faults.

Determining the improper use of units.

Status checks on new and repaired units.

Convenient scheduling of repairs.

Monitoring of units under overload.

FURAN ANALYSIS

Periodical evaluation of furan compound in the oil help to know the condition of paper insulation. The mechanical properties of insulating paper can be established by direct Measurement of its tensile strength or degree of polymerization (DP). Direct measurement of these properties is not practical for in-service transformers since It requires removal of a few strips of paper from suspect sites.

This procedure can conveniently be carried out during transformer repairs. The results of These tests will be a deciding factor in rebuilding or scrapping a transformer. Since it is usually not practical (and often dangerous to the transformer) to obtain a paper sample from a de-energized, in-service transformer an alternative method has been found.

When a cellulose molecule de-polymerizes (breaks into smaller lengths or ring structures), a chemical compound known as a furan is formed. By measuring the quantity and types of furans present in a transformer oil sample, the paper insulation overall DP can be inferred with a high degree of confidence. The types and concentration of furans in an oil sample can also indicate abnormal stress in a transformer, whether intense, short duration overheating or prolonged, general overheating.